AEM Water/Methanol FAILSAFE Gauge for AEM kits

AEM Water/Methanol Injection Monitor - A revolutionary failsafe from AEM

The most advanced, easy to use active water/methanol safety device on the market.

- Use your water/methanol injection system with complete peace of mind

- Easy to set up and use

- Smart and sophisticated system that actively monitors the entire flow curve

OVERVIEW

Actively Monitors ENTIRE Flow Curve to Prevent Engine Damage!

Delivers Complete Peace of Mind If Your Water/Methanol System Experiences a Failure

AEM's Water/Methanol FAILSAFE Device is the most advanced water/methanol failsafe device on the market. It actively monitors the injection system's ENTIRE flow curve to compensate for failure under ANY condition, allowing you to use your water/methanol system with complete peace of mind. If you have a water/methanol injection system or are considering one, you will not find a more advanced failsafe device on the market than the AEM Water/Methanol FAILSAFE Device.

WHY YOU NEED THIS

Today's water/methanol injection systems have proven themselves as a viable means for effectively reducing engine inlet air temperatures and suppressing harmful detonation. This allows enthusiasts to reliably increase boost and advance ignition timing without the need for racing fuel. Despite the proven effectiveness and reliability of water/methanol injection, there exists a potential for engine damage if the water/methanol tank runs dry, if the pump stops working or more commonly if flow volume decreases due to fuel contamination, a clogged nozzle or a leak in the system.

While failsafe devices for water/methanol are not new, competitors' failsafe systems have limitations that do not allow them to completely protect your engine if the water/methanol injection system stops flowing. Most failsafe devices have settings for high and low range flow parameters, but only monitor flow at a single point. And, without actually calculating volume versus time to establish a flow rate, instead running the system at full blast and using the nozzle's potential for flow as your established flow rate, it is impossible to know the actual flow of the water/methanol system. Short version: if you think you are flowing 500cc/min and are actually flowing 300cc/min, and you are relying on your failsafe to trigger an alarm at a single reference point using 500cc/min of flow as your reference, then you have created the potential for engine damage.

Other competitors' failsafe systems use a flow meter to establish water/methanol flow and utilize an external adjustment to trigger an alarm if the system does not detect maximum flow, using a time-delay strategy to compensate for part throttle operation. The problem is, water/methanol flow is rarely zero or maximum flow, and with all of the potential flow rates one can experience, a time delay strategy is not completely failsafe.

WHAT MAKES AEM'S WATER/METHANOL FAILSAFE DEVICE UNIQUE

AEM's Water/Methanol FAILSAFE Device actively monitors the entire flow curve independent of pressure, continuously collecting flow vs. injection rate data so that any deviation from your established flow curve will trigger an alarm output that can be used to reduce boost or timing, change maps, add fuel, trigger a two-step or perform practically any action you choose to save your engine. It is PC programmable (with USB connectivity) which eliminates the guesswork when setting min/max threshold parameters. It features PC-based software and an auto-scaling flow map that simplifies set up, and has an "Auto Set" feature that will create a baseline configuration.

HOW IT WORKS

Should an alarm trigger, the AEM Water/Methanol FAILSAFE Device has one low-side (ground) driver and one high-side (+12v) driver that can be configured to turn on or off during an alarm condition. For instance, late-model Subaru WRX STi owners can connect the low-side driver to the 'limp' wire behind the kick panel that will dump boost and pull timing via the factory ECU. If you have a supercharged Chevy 350cid small-block, you can use it to pull timing from a switched aftermarket ignition system. The possibilities are endless.

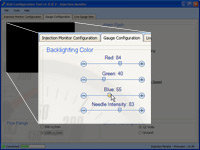

A high-tech analog gauge is included with the AEM Water/Methanol FAILSAFE Device, with programmable backlighting to match your factory gauges. The gauge needle and backlighting can be configured to flash when an alarm is triggered to notify of a potential system error.This system also includes an internal data logger that records injection and alarm status data for future reference.

Water/Methanol FAILSAFE Device Racer Features

- Actively monitors the entire water/methanol fuel injection curve to trigger an alarm event under any defined adverse condition!

- "Auto Set" feature automatically creates baseline configuration

- Built-in warning lights inform user of an alarm trigger

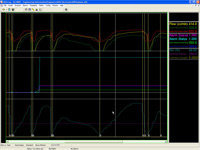

- Internal data logger records all injection flow and alarm status data

- Included high-tech analog gauge has black and white faceplates and bezels to match vehicle interior, and is programmable for either 0-500cc/min or 0-1000cc/min flow ranges

- Gauge alarm and backlighting are user programmable to match interior lighting

Water/Methanol FAILSAFE Device Tuner Features

- Tunable PC-based software with USB connectivity

- One low-side (ground) driver and one high-side (+12V) driver can be configured to turn on or off during an alarm condition

- Fully adjustable alarm delay and reset period

- 0-5v Analog output for use with data loggers and virtually all engine management systems

- Auxiliary input for use with AEM Water/Methanol "Boost Safe" feature can trigger an alarm event if there is a system readiness issue (open circuit, short circuit, low fluid level, etc.)

- Precision flow sensor included

Setting up the AEM Water/Methanol FAILSAFE device is easy!

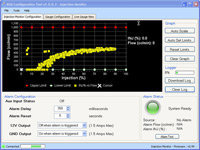

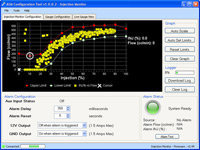

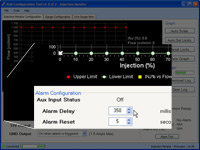

Start by taking several pulls to establish a baseline flow curve. This information will be stored in the software and viewable on the auto-scaling graph.

Once your flow curve is established, set your high and low flow limit curves. Our Auto Set Limits feature can do this automatically for you.

Once you have established your injection/flow limits, set the Alarm Delay (in milliseconds) to optimize performance, and then set your alarm reset time.

The last step is to configure your outputs to perform a desired function in the event an alarm is triggered. The possibilities are endless. Cut timing or boost, add fuel, switch maps…it's your call! After this step is complete, you can use your water/methanol injection system with complete peace of mind.

Now to the fun part! Our multi-color LEDs allow you to perfectly match your OEM or aftermarket gauge lighting, and we include black and white face plates with black and silver bezels. Both needle and backlighting are fully user definable.

If you never disconnect your laptop, flow and injection rates are viewable on the software's live analog gauge view.

If something goes wrong, the AEM Water/Methanol FAILSAFE Device will protect your engine. But you are still going to want to know what triggered that high- or low-side alarm. Our FAILSAFE has an internal data logger that records all injection and alarm status data for later viewing.

NOTE :

FOR OPTIMUM RESULTS, ALL WATER/METHANOL INJECTION SYSTEMS AND GAUGES SHOULD BE RUN WITH AN AEM INLINE FILTER (AEM PART #30-3003)

Important Safety Notice Regarding Methanol

AEM strongly recommends that users never exceed a 50% methanol concentration when using any AEM Water Methanol system or component.

All AEM Water/Meth injection systems and components (pump, lines, fittings, filter, flow sensor, tank, and nozzles) are 100% chemically compatible with methanol. However, for safety reasons we strongly recommend that users never use more than a 50% methanol concentration in our systems.

Methanol is a toxic and highly flammable chemical. 100% Methanol ignites easily and burns vigorously with an almost undetectable flame. Methanol can be absorbed through the skin and even x-small amounts can cause blindness or even death. Using this fluid at high pressures, without dilution, in an under-hood environment with nylon lines and push-to-connect fittings is very unsafe. The performance advantages of using greater than 50% methanol concentrations are x-small, if they exist at all. However, the safety issues are very real and far out weigh any perceived benefit of running high concentrations of methanol.

WARNING!

Improper installation and/or adjustment of this product can result in major engine/vehicle damage. For technical assistance visit our forum visit our reseller page to find a professional installer/tuner near you.

Note: AEM holds no responsibility for any engine damage or personal injury that results from the misuse of this product, including but not limited to injury or death caused by the mishandling of methanol.